18 Liter Can

With innovative technology, our steel packaging complies with current standards and legislation, guarantees maximum safety and is approved for the transportation of dangerous goods.

CAN

18 LITERS

Industries of solvent-based paints, chemicals, adhesives, chemical pesticides and other items considered dangerous need to have an alternative for steel packaging that fully meets the requirements of the legislation in accordance with the procedures recommended by the UN - United Nations.

Request Specifications "

The norms and standards applied internationally, based on the recommendations issued by the United Nations Committee of Experts on the Transport of Dangerous Goods, provide the definitions and information on the necessary tests and the standardization of the codification. Due to their physicochemical characteristics, hazardous products may contain substances triggered by various processes that pose a risk to human health, public safety or the environment. In order to avoid risk during transport, the tests require greater resistance of the packaging system in the face of impacts and in the face of increased internal pressure. For bottlers, the ideal is for the system to be restricted to the packaging itself, which would avoid the use of composite packaging. In this case, the free fall of the package filled with the product, without any additional protection, is one of the rigorous tests that the package is submitted to obtain approval for the transport of dangerous products.

CODE OF

CONDUCT AND ETHICS

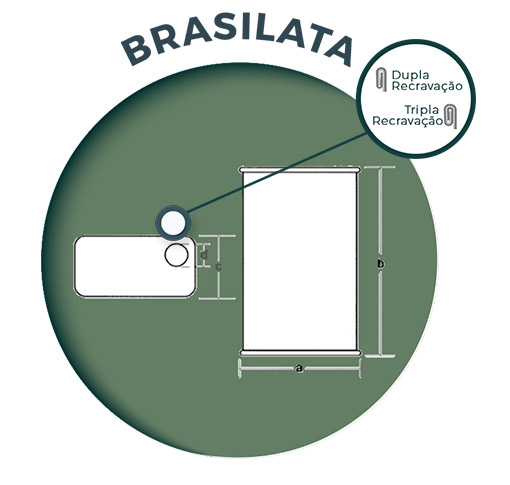

In the case of paints and other solvent-based chemicals, the standard provides for a drop from a height of 1.20 m. This test is particularly critical for the 18-liter square can, especially when the package falls on its corner, which can cause the seam to break (body hooking with the bottom/ring).

The classic solution to this type of problem is to increase the thickness of the steel sheet, combined with reinforcement in the system, which replaces the traditional double crimping with triple crimping. However, the option for triple seaming requires investment in new equipment (seaming machines) and, in addition, implies greater consumption of raw materials and reformulation of production processes.Our technical team devised a system to relieve part of the stress suffered by the seam during impact. The studies led to a solution that led to the absorption of the energy of the fall by increasing the deformation of the body, consequently alleviating the efforts in the seaming.

Seaming

We had the support of the Universidade Federal do Rio Grande do Sul in the study to determine the ideal profile and the number of friezes. The use of sawtooth type friezes presented the best result for impact and the greatest stress reduction in the seaming region.

Such results were obtained through a dynamic non-linear finite element analysis of the falling behavior, varying the profile types and their quantities, since the problem involves large displacements and permanent deformation of the package. Ansys software was used to carry out the simulations.

The geometric models are submitted to the simulation of a fall, and the results are compared to real falls to validate and improve the mathematical models used. Because it is an innovative technology, we filed an international patent.

OUR SEGMENTS

We have a complete portfolio of metal packaging in different sizes and formats to adequately meet every need. Discover the ideal solution for your demand.